Common Cathode LED Display Introduction

Recently, the power supply technology of the common cathode LED display has attracted much attention. This method could save about 75% of energy. How could it be so excellent?

First, we need to know what is the common cathode LED display. Common cathode means to supply electricity with the common cathode, which supplies power for red, green, blue separately. This could distribute voltage and current to the red, green, blue LED lamps precisely. The current would get to the IC cathode from the LED lamps. This would bring a low forward voltage drop and small conduction resistance.

Common Anode VS Common Cathode

☛ Common anode LED display current would get to the LED lamps from the PCB board and RGB LED lamps would supply power together, which could make a higher forward voltage drop. For a common cathode LED display, just as mentioned above, it could make a low forward voltage drop.

☛ Common anode LED display distributes a voltage more than 3.8V (5V for instance) to red, green, blue LED lamps to supply power together. As a result, this could cause a big power loss. For common cathode LED display, it is to supply power separately based on the voltage needed of red, green, blue LED lamps (it is about 2.5V for the red LED, while it is 3.8V for blue and green LEDs). This makes little power loss and the heat is much less during the operation of an LED screen.

Why the Heat of Common Cathode LED Display is Much Less?

From the introduction of the common anode and common cathode supplying power, we could know the power used for a common cathode LED screen would be much lower than that of a common anode LED screen (regular LED screen), and the heat of the former would be much less than that of the latter.

Here are 2 points of common cathode LED:

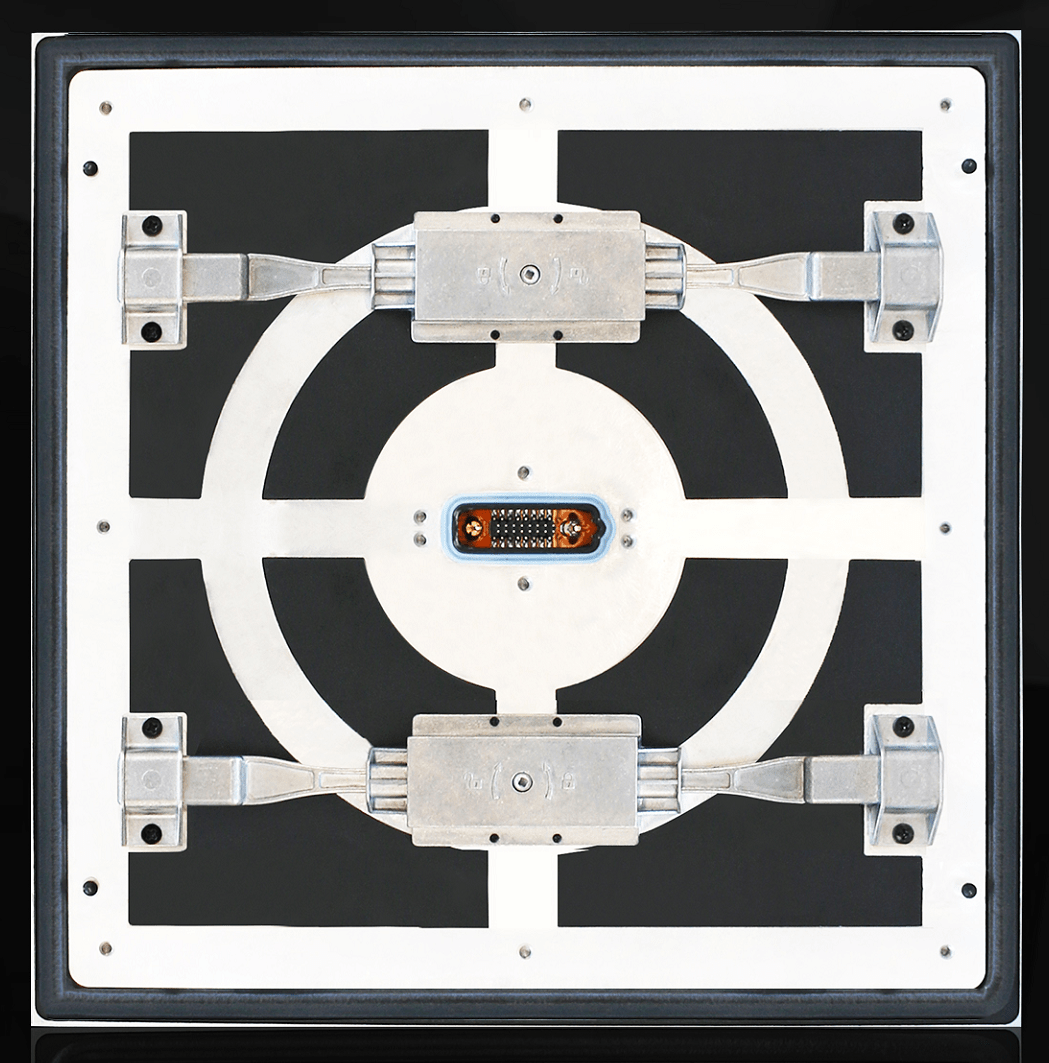

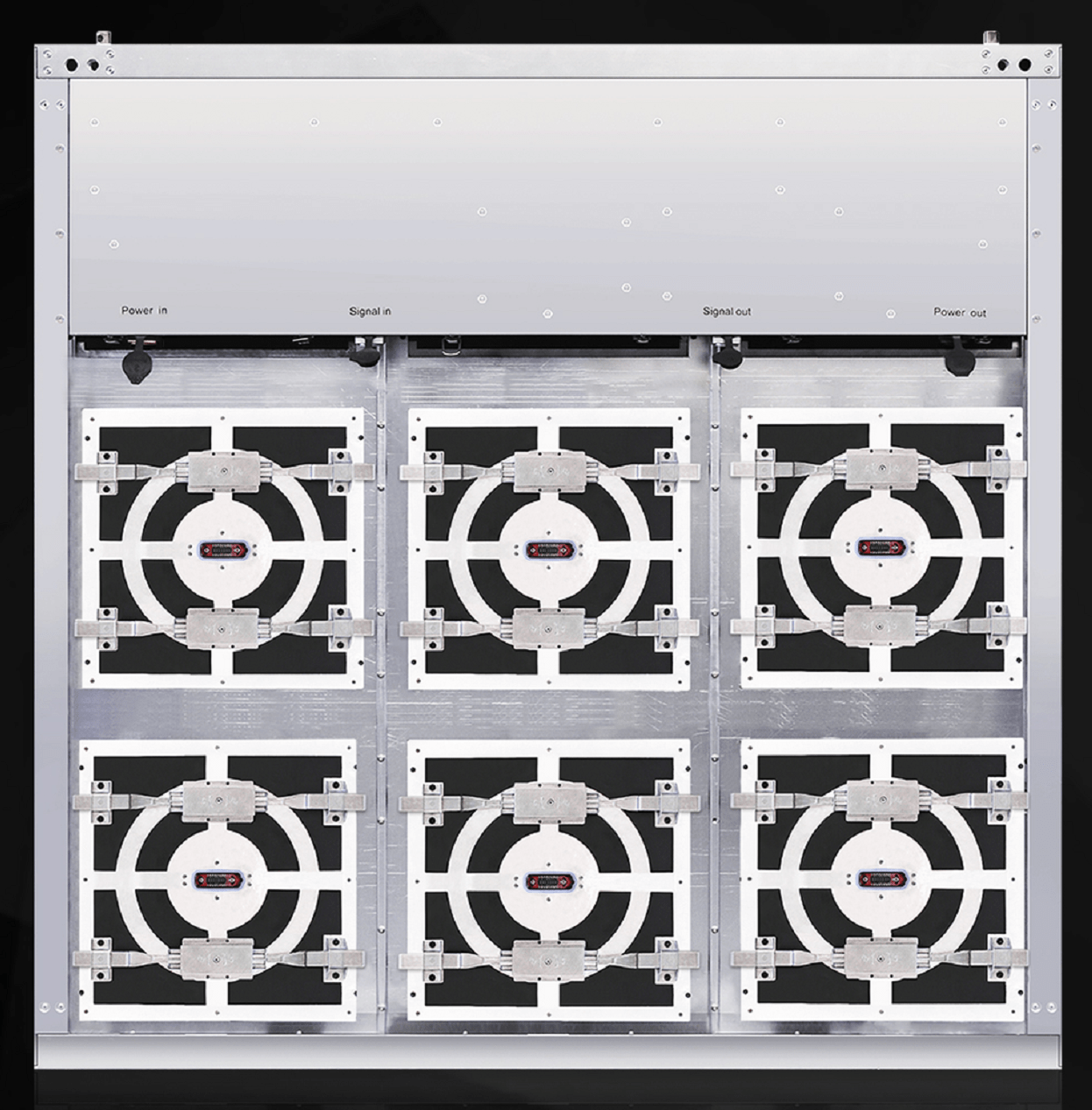

▶ The aluminum base of LED modules is adopted. The heat on PCB would be transferred according to the aluminum base. This aluminum base would be the cooling fan for LED lamps and drive ICs. As it is die-casting aluminum made, the flatness of the whole LED screen would be much better. Besides, the weight is less. For example, for a common anode LED screen with 960x960mm LED panel size, the weight is about 34 kg. For this common cathode LED screen with aluminum bases with the same panel size, it is about 29 kg.

▶ For the aluminum base, it has the function of anti-electromagnetic interference and anti-radiation. This could meet the standard of export to EU countries and the USA.

Common Cathode LED Display Advantages

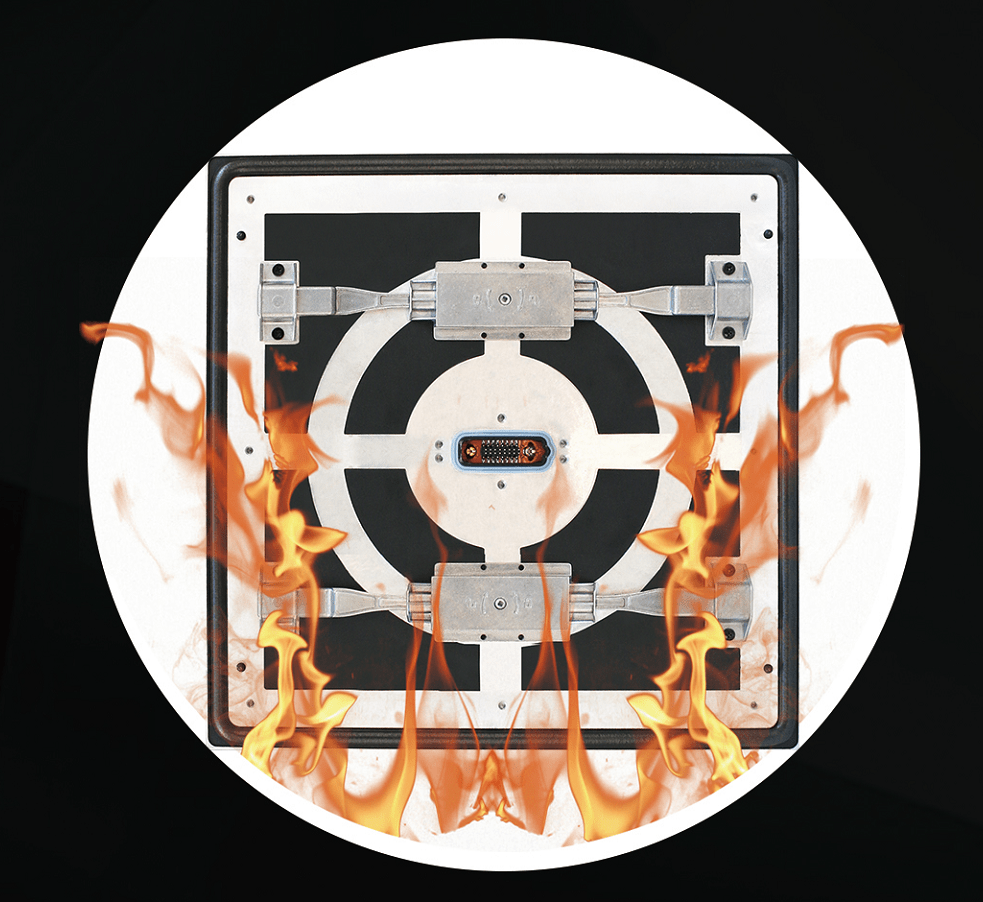

- Strong heat dissipation, low power loss, low heat, long life span.

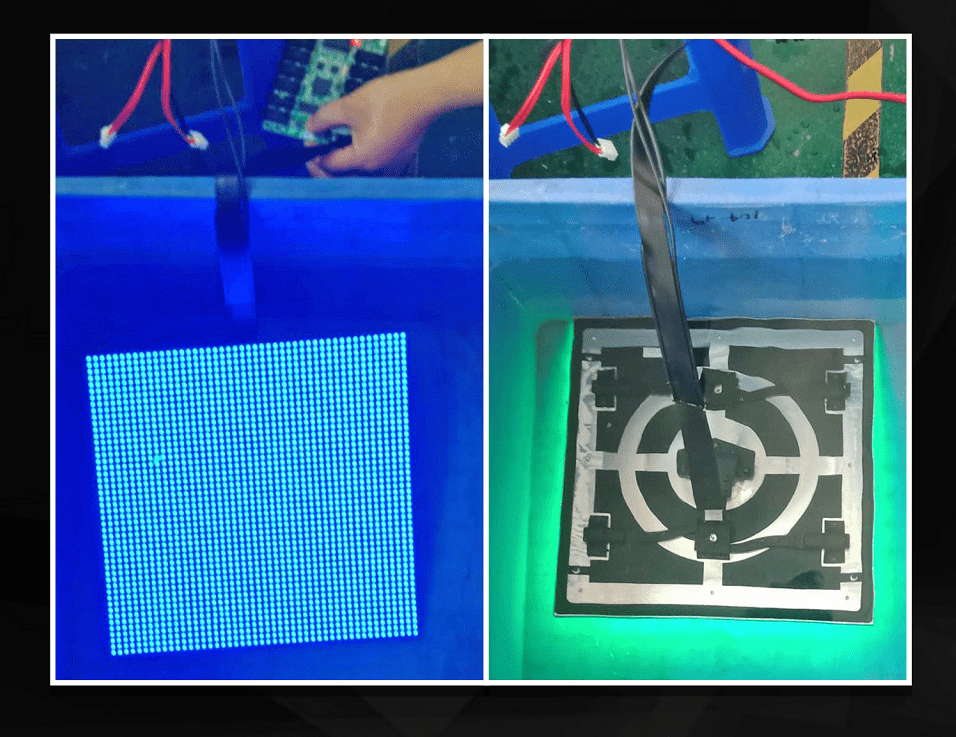

- High-grade waterproof (IP68 grade), dust-proof, anticorrosion, UV resistance, V0 fireproofing grade. It could be under the test of the highest temperature like 130℃, and it could also work without a problem under 3 meters of water.

- Front and back maintenance.

- High brightness about 5,500 nits.

- Real energy-saving, could achieve about 75% of energy efficiency.