How to Buy LED Screen with Good Quality? — 5 Tips

It is more or less confusing when making a decision to buy LED screen with stable quality. Except for an important factor of LED screen price, here are 5 tips that are useful to help you get a good LED screen.

☛ The highest brightness: It refers to the brightness at the 255 brightness scale when setting with the LED screen software and using the luminance colorimeter to test. For different locations of outdoor LED screens, it is different for the brightness requirement. For instance, if the screen is facing the south and the sunlight is shining at the LED screen most of the time during the day, then the brightness should be about 7,000 nits. Otherwise, the contents on the screen couldn’t be seen clearly. If there is little sunlight during the daytime, then it is OK to use the type with 5,500 nits or less.

☛ Color temp: If the color on the LED screen is different from that showing on the control PC, it is a serious distortion. This is relevant to the color temp of the white balance of the LED screen. If seeing the LED screen with naked eyes directly, then the color temp of white balance needs to be 6500~8000K.

☛ Refresh rate: It refers to the times of the LED screen to show contents completely in every second. If the refresh rate is too low like less than 300Hz, then there would be a jittering phenomenon of the LED screen when seeing with naked eyes. And there would be scan lines when taking photos at the LED screen with a camera if it is less than 1,000Hz. With a high refresh rate LED screen, you could take photos or videos without scan lines. This is very important for rental LED display projects.

☛ Wavelength: Wavelength decides whether the LED screen color is pure. Then how to decide with naked eyes? Here are two points:

- When the LED screen is testing with white balance, it should be pure white and no other mixed colors. If there is a little red or blue, then there are some problems with raw materials or workmanship. It would get worse if the LED screen operates longer.

- When the LED screen is testing with red, green, blue, it would be pure red, pure green, pure blue. If it shows darker or lighter color, it means the LED colors are not pure. If it is different for one specific color, it means the wavelength difference is big. For a high quality LED screen, the blue and green LED wavelength difference needs to be within 4nm, while the red LED wavelength difference should be within 5nm.

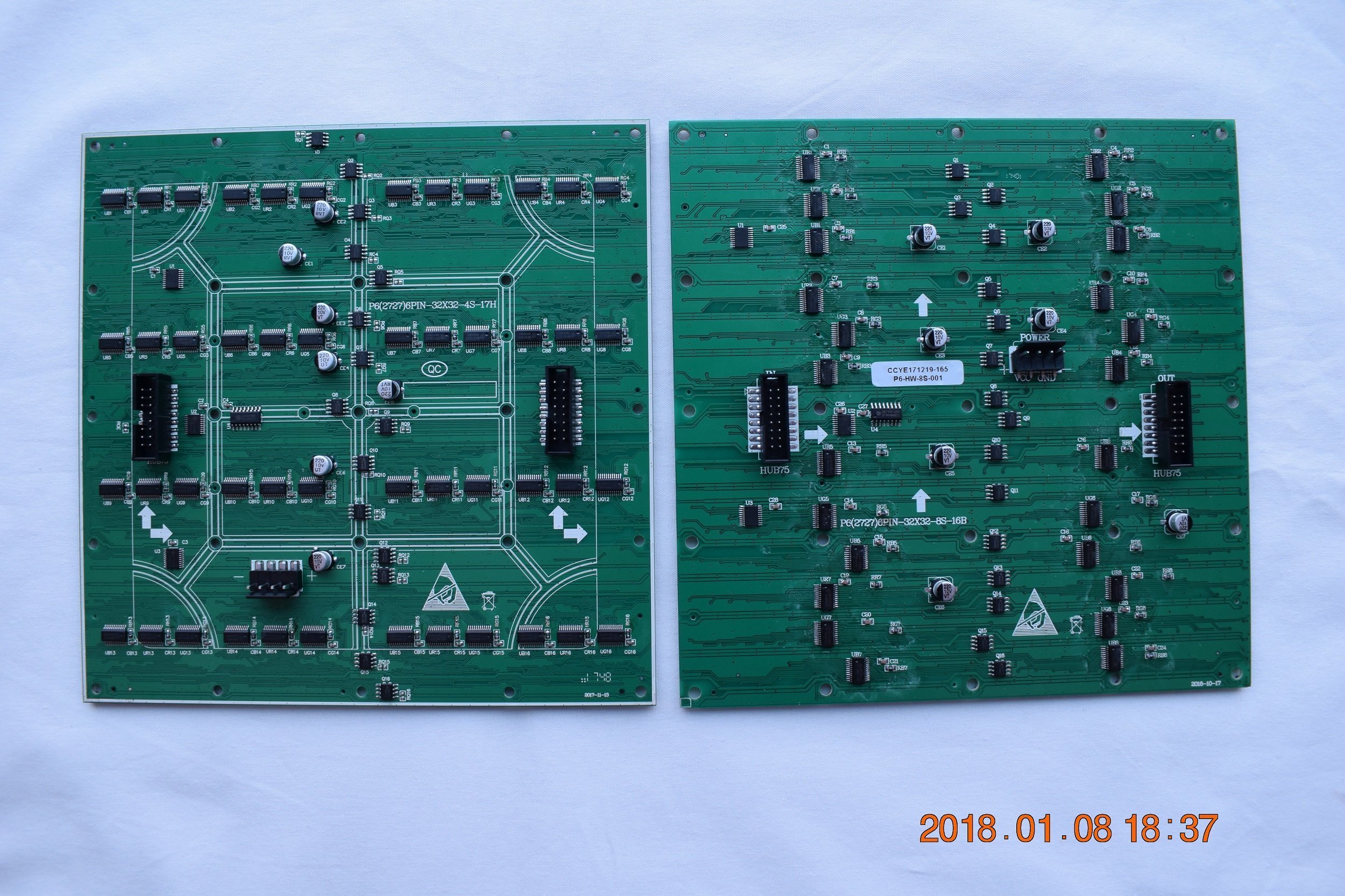

☛ Electric circuit: The PCB is very important for an LED screen. Generally, it should be with 1.6mm thickness. But now most suppliers make LED screen with only 1.2mm or 1.0mm or 0.8mm thickness. For the type with 1.6mm thickness, the copper foil on it is 35um thickness. For those with thinner PCB, the copper foil is only about 18um thickness. The thicker PCB copper foil, the better heat dissipation. And it is with much higher stability with thicker PCB copper foil. For the Dreamway LED screens, we use 1.6mm thickness PCB for all LED screen projects. Below are photos with 1.6mm thickness PCB:

If you are looking to buy LED screen with stable quality, please contact us to get a professional solution.