P10 LED Display with DIP346 Type Project:

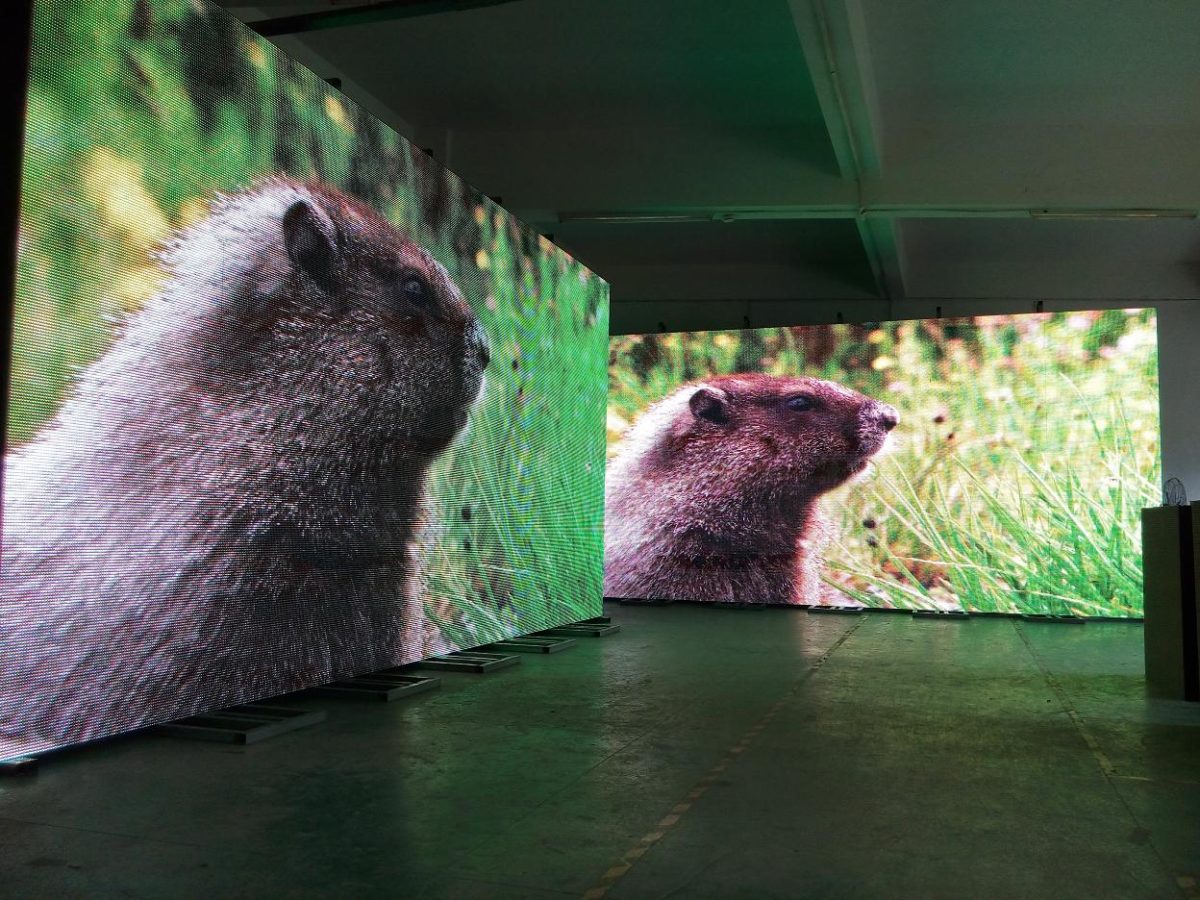

This project was finished in 2015 in Israel. The client inquired about taxi top LED display at first. After he came to visit our factory in March 2015, he signed a contract with us of 110 pcs P10 LED display cabinet, with 960×960 mm each.

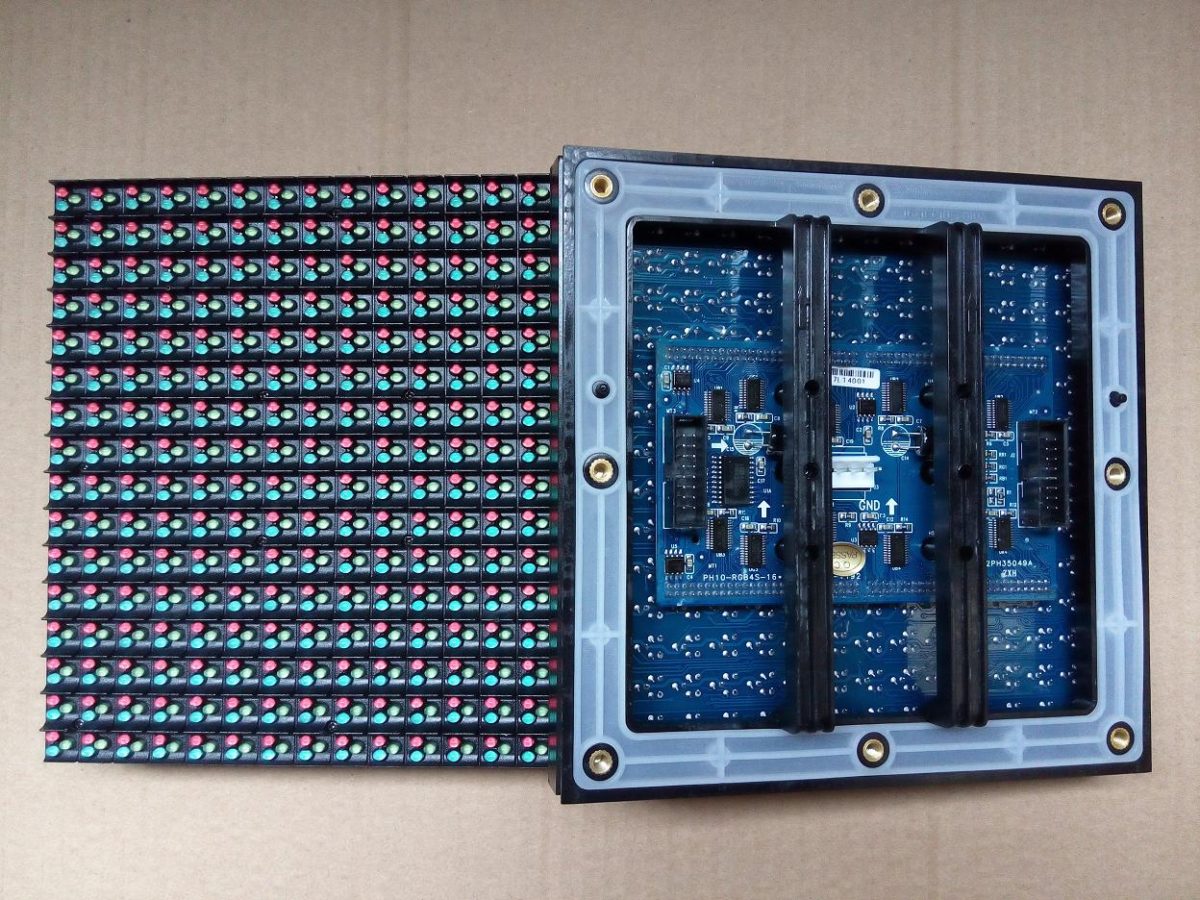

For this P10 LED display, the LED lamp is DIP346. DIP means a dual in-line package. According to Wiki, it is an electronic component package with a rectangular housing and two parallel rows of electrical connecting pins. The P10 LED panel of this project is 160×160 mm, with 16×16 dots. This DIP LED panel is with 1/4 constant current, about 6,500 nits.

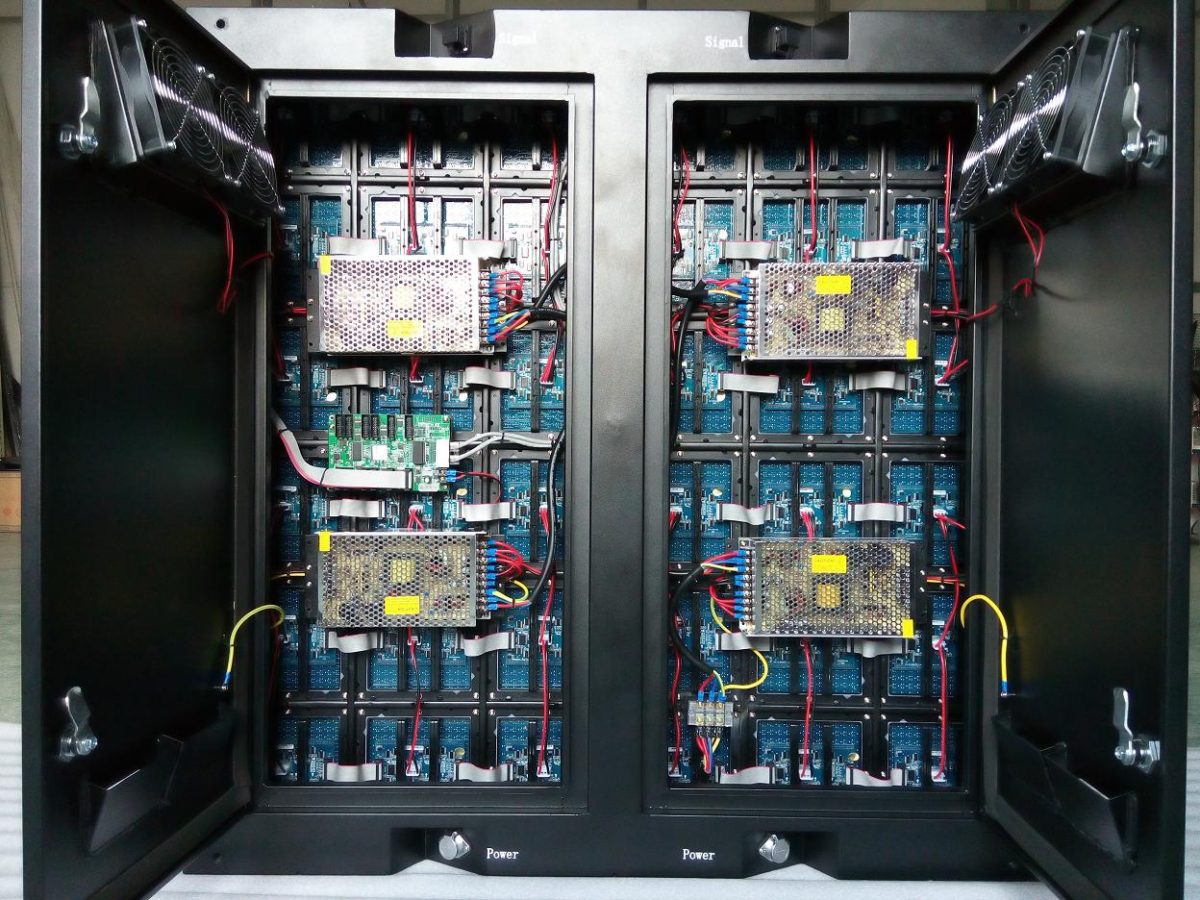

For this LED DIP screen, each cabinet is equipped with 6×6 pcs LED panels, 4 pcs power supplies with 5V40A each, 4 pcs cooling fans and 1 pc Novastar MRV300 receiving card. Besides, Linko power and signal connectors are equipped for easy connection during the installation. Each P10 LED display cabinet weighs about 42 kg.

During the aging, each P10 LED display was set up with W 5.76 x H 2.88 meters, with W 576 x H 288 pixels. This is one common LED screen size ordered mostly by clients. It is composed of W 6 x H 3 pcs cabinets with 960×960 mm each. Per P10 LED display was aging at least 7 days before the package.

For this P10 LED display project, 2 pcs cabinets were packed in 1 pc plywood case. And they were shipped in a 20′ container.

LED DIP Screen Existence Value:

Several years ago, with the development of SMD LED type, DIP LED became less applied for outdoor projects even though it had been adopting for so many years before.

Here are some points of SMD VS DIP:

- SMD LED has a better-displaying effect than that of DIP, as the color mixture of the former one is much better.

- SMD LED has a bigger viewing angle than that of DIP, which makes sure a bigger audience range.

- SMD LED is with lower brightness than that of DIP based on the same type, but with higher power consumption.

From the above, although SMD LED has many more advantages, DIP LED is still now preferred for some special or big outdoor projects. Here are some features of DIP type:

☛ The overall dimension of one single DIP LED is 3.0×4.1×6.3mm. One pixel is composed of a red LED, a green LED and a blue LED. Each LED lamp encapsulates only one chip. Besides, because of its long lamp pin, it could reach to much high brightness and no need to increase the current. Thus it is not a problem of heat dissipation. All these make sure less failure rate and attenuation rate.

☛ The DIP LED lamp is soldered through the pad of the PCB, which makes much more stable soldering. This could prevent cold soldering problem from occurring during the transportation or operation. As a result, the maintenance cost would be much lower.

☛ Silicone is used mostly for the waterproof aspect of the DIP LED, with 3.5~4.5mm thickness. This is much thicker than that of SMD type. Thus DIP is much better in waterproof, damp proof, ultraviolet-proof or other severe environments.

If you are looking to purchase a P10 LED display, please contact us to offer you a professional solution.