P3 Screen LED Wall Project:

For this SMD P3 screen, it was installed at Banjul airport, Gambia. It was finished at the beginning of 2019. There are 2 units in the total of this project.

The LED screen size of each 3mm LED wall is W 2.304 x H 1.536 meters, with total resolution W 768 x H 512 pixels.

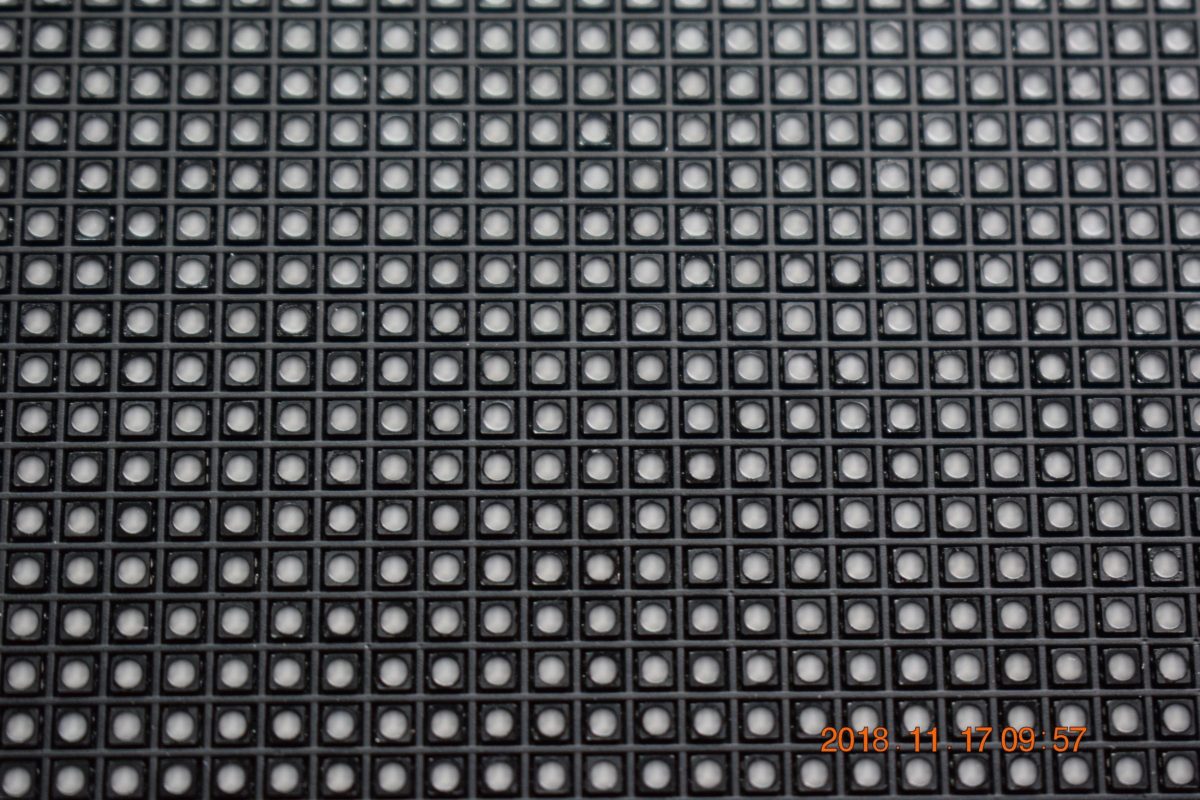

It is composed of W 12 x H 8 pcs LED modules. For P3 LED module, it is with 64 x 64 dots, 192 x 192 mm. The LED lamp adopted is matte black type, with stable quality. It is an SMD2121 type. The drive IC is 2038S, with a 1,920Hz refresh rate. Besides, the LED module mask is covered for this P3 screen LED module, which could protect LED lamps from damage.

For the cabinet of this P3 smart LED video wall, it is made with iron material. The LED screen cabinet size is W 768 x H 768 mm, with W 256 x H 256 pixels. As it is installed on the wall and there is no space at the back to maintain, this cabinet is designed with front service. There are magnets at the back of LED screen modules to attach to the cabinet to make it front service. Each LED panel weighs 15 kg.

Each cabinet of this P3 screen LED wall video is equipped with 2 pcs power supplies, fanless, and 2 pcs receiving cards.

Besides, a video processor is equipped for this P3 screen. It is to get HDMI input signals. Also, it is more convenient for clients to operate after they receive the goods.

For this P3 screen, it was aging for more than 7 days in our factory before the delivery. Aging is an important process to make sure the LED screen quality is stable. And it is also important to set the LED screen with all white, red, green, blue colors in turn during the aging. Of course, static images or videos are also needed during the aging. Once the LED screen works in such a condition with a high and low temperature that some minor problems could come out. This could prevent clients from receiving defective goods.

Before the package, we disassembled the LED modules at the corner of each LED panel and packed with spare parts. Because this is front maintenance and there is no space at the back, that means clients could only install this P3 screen from the front, this makes cables connection a big problem. So we disassembled LED modules before the package, and clients could connect cables between the two cabinets first and then put LED modules to the cabinets. This makes them much easier during the installation.

After the package, the goods could be delivered. And this is a whole project procedure during the operation in our working shop.

If you are interested to know more, please contact us.